Society

Social Contribution Activities

Social Contribution Vision

The FSG vision is that "Our Value to People and the Planet".

We aim to be a company that is resonsible for the realization of a sustainable society. We will continue to be a company that delivers affluence, happiness, pleasure and peace of mind to society and consumers through the development of people-friendly packages that are "easy to hold", "easy to open", "easy to read" and "easy to dispose".

FSG will fulfill our responsibilities as a member of the local community by maintaining good relationship, solidarity and cooperation with the local community.In addition to conducting business activities with respect for the customs and culture of the local community, we will participate in and cooperate with the activities of local communities and actively support voluantary social contribution activities of our employees.

Communication with the local community

- Japan

-

- Participated in the “Nabari Clean-Up Campaign,” a citywide cleanup activity held throughout Nabari City.

This event engages many local residents and companies every year. (June, 2024) - Collaborated with players from the professional basketball team Wavens Yamagata to clean up trash at the local rest area in Sagae, Yamagata. (July, 2024)

- Organized a mobile blood donation drive at the SXS Center (38 participants)(July, 2024)

- Participated in the “Nabari Clean-Up Campaign,” a citywide cleanup activity held throughout Nabari City.

- Europe

-

- Crisp (Potato chips) Packet to Blankets

Crisp packets, which are believed to take 80 years to decompose, provide a sustainable alternative to throwing them away and can provide a lifeline for people on the streets.

We are using rubbish to make something that somebody can use, and the packets would be waste if not recycled this way.(Ongoing from 2020)

- Crisp (Potato chips) Packet to Blankets

- Americas

-

- American Fuji Seal (Bardstown) participated in the Annual Kiwanis Christmas Parade and introducing AFS's history and business (December,2023)

- Fuji Seal Mexico employees visited a facility for the elderly, donated nutritional supplements and diapers, and spent time talking with the residents.(May, 2024)

- Scholarships awarded to students residing in Nelson County, USA, who are majoring in fields related to Fuji Seal's business (June, 2024)

- ASEAN

-

- Participated in a tree planting project activity aimed at preventing global warming at the Sinsakhon Industrial Estate in Samut Sakhon, Thailand.(August, 2024)

- Guest lecturer at Kasetsart University in Thailand on topics related to the development and specifications of shrink sleeve labels and soft pouches (August,2024)

- Donated financial support to assist residents in Northern Vietnam affected by Typhoon No. 3 (September, 2024)

Development of people-friendly packaging materials

Fuji Seal develops and provides people-friendly packaging materials, such as easy-to-hold products, light-weight products, and easy-to-read products.

We have so far strived through trial and error to resolve various customer issues. Although we have suffered numer-ous failures during this process, we have worked with determi-nation to resolve the issues and overcome these failures. We believe that this has enabled our products to be widely adopt-ed in various industries.

Shrink Sleeve Labels

Wider space for display and sealing function

Tamper-proof shrink sleeve labels were adopted for a new type of light-weight and shatter-proof bottles.

These light-weight and shatter-proof containers are not only easy for the user to hold and pour, but also contribute to the reduction of greenhouse gas emissions. The wider space for display makes it easier to read a display on a label. Moreover, perforat-ed labels are easy to peel off, enabling the easy separation of labels.

Pressure Sensitive Labels

Easy-to-read display

Booklet-type labels with a wider space for display can provide a great deal of informa-tion. They serve not only as descriptions of new products but also as package leaflets which are hard to lose.

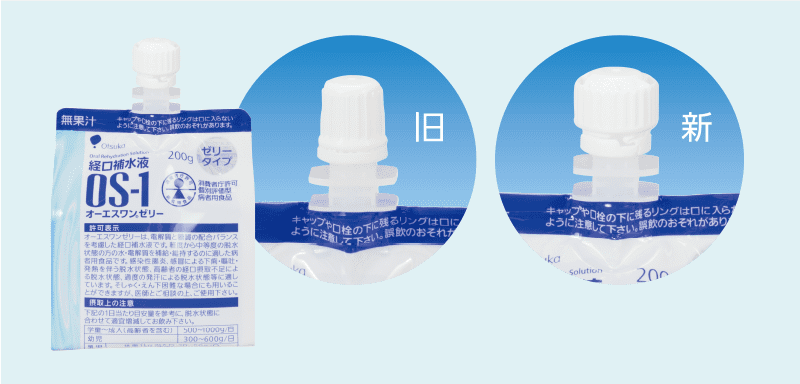

Spouted Pouches

Easier to open

Spouted pouches with easier-to-open caps were developed, so that they can be easily opened even by those who are weak-handed or do not have enough finger strength. These pouches are well received by our customers (consumers).

- Display of necessary information

- Safety and security

- Easy to read

- Easy to open

- Light-weight /Easy to hold

- Easy to dispose of

Fuji Seal Foundation

This program was launched in fiscal 2006 to provide scholarships to undergraduate and graduate students in Japan and overseas, as well as international students studying in Japan. Since then, we have sponsored the Asia Student Package Design Competition (ASPaC) and provided grants to researchers studying topics related to packaging.

Fuji Seal Foundation

Safety, Health, and Accident Prevention

The Fuji Seal Group places top priority on the safety and health of employees. We plan and take safety, health and accident prevention measures in a responsible manner to continue to ensure the safety and health of employees at each company and work site.

Safety, health and accident prevention management system

In each business region, an executive officer is responsible for safety, health, and accident prevention, and, at each company and factory, a Safety, Health and Accident Prevention Committee is established. In addition, information on minor incidents on-site is shared among the Group in order to take preventive measures.

We have also built a system in which, in the case of a labor accident and a fire, similar potential sites are promptly checked in all business regions and preventive measures are rolled out. We enhance our efforts to learn from past failures and to accumulate and standardize know-how about preventing accidents. In particular, to comply with laws, regulations, and internal rules, including auditing BCP.

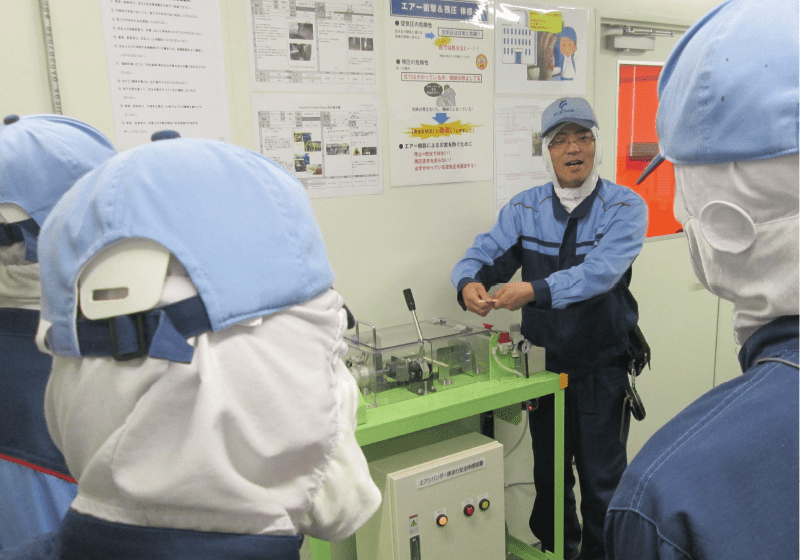

Installation of imitative risk experience facilities

Imitative risk experience facilities are installed at factories in Japan, where subjects can actually experience the risk of being involved in a labor accident. These facilities are set up so that employees can experience potential risks in the workplace to learn the importance of safety physically and mentally, thereby improving their ability to prevent labor accidents from occurring and foresee potential risks.

Employees experience these imitative risks when joining the company as well as on a regular basis to raise their safety awareness.