Fuji Seal Group's ESG History

What is required of ESG practitioners changes over time. Our customers are always responsible for ESG compliance and take the lead on ESG. To continue doing business with these customers, the Fuji Seal Group is required to continue to implement ESG-oriented management. We have developed together with our customers, suppliers, and employees.

Environment

Realization through products

- No waste containers

- Reduction of material use

- Recycle

- Waste reduction

- Reduction of transport costs

- Reduction of CO2 emissions

-

2020-

- System for the industry's thinnest 20 µm-labels

- Recycled PET wrap-around labels with a thickness of 18 µm Shrink function leading to the standardization of containers for compact detergent

- Metal beverage bottles (standardization of bottles leading to inventory reduction)

- Shrink cardboard helping to reduce plastic use

- Fuji Pouch

- Non-box packaging with the use of a booklet

- Dry steam shrink tunnel contributing to the reduction of CO2 emissions

- RecShrink labels recyclable with PET bottles into bottles

-

2010-

- Drinkable yogurt: Standardized containers + Shrink sleeve labels

- Environmentally friendly labels: Biodegradable labels, recycled PET labels, low-density labels, white PET labels, olefin labels (Europe)

- Reusable plastic cartons + Containers

- Energy-saving heaters

- Multiple refill pouches helping to reduce plastic use

- Plastic-saving container pouches

- World's fastest pouch system helping to increase productivity

-

2000-

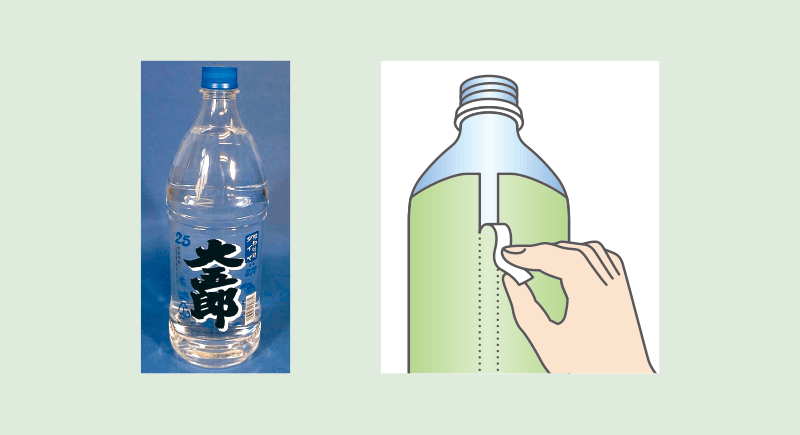

- Containers and Packaging Recycling Act: Transparent bottles + Shrink sleeve labels + Development of perforated labels

- De-label tack

- Off-mold label - Cap seals made of biodegradable film adopted for processed foods

- Development of high-speed stretch labelers and shrink sleeve labelers leading to increased productivity

- Development of a roll feeder system: Reduction of carton boxes to be used for shipping and productivity improvement at customers

- Containers and Packaging Recycling Act: Transparent bottles + Shrink sleeve labels + Development of perforated labels

-

1990-

- Change from direct printing to the use of shrink sleeve labels leading to the standardization of containers, resulting in the reduction of container inventory

- PET bottles + Shrink sleeve labels

- Development of non-PVC film: OPS for PET shrink sleeve labels

- Customer productivity increased due to high-speed labelers