Environment

Environmental Policy

We recognize that environmental issues are important issues common to all human beings. In order to contribute to a bright future and a livable global environment, we have established an environmental policy since 2008 and have conducted our business activities in consideration of environmental aspects.

In 2021, we completely revised our environmental policy where we will continue to contribute positively to the realization of a sustainable society by having each and every employee involved in more environmental activities and by further promoting cooperation among supply chains.

Environment Management System

Under the direction of the CEO, we have been implementing environmental initiatives for years in mutual collaboration at the Group and regional levels in accordance with the Group's Basic Environmental Policy. In addition, ESG management will be promoted even more than before by setting environment-related targets, monitoring progress, and evaluating what has been achieved in the Group Sustainability Committee, a meeting body under the direct control of the CEO and executive officers.

Environmental Visions and Targets

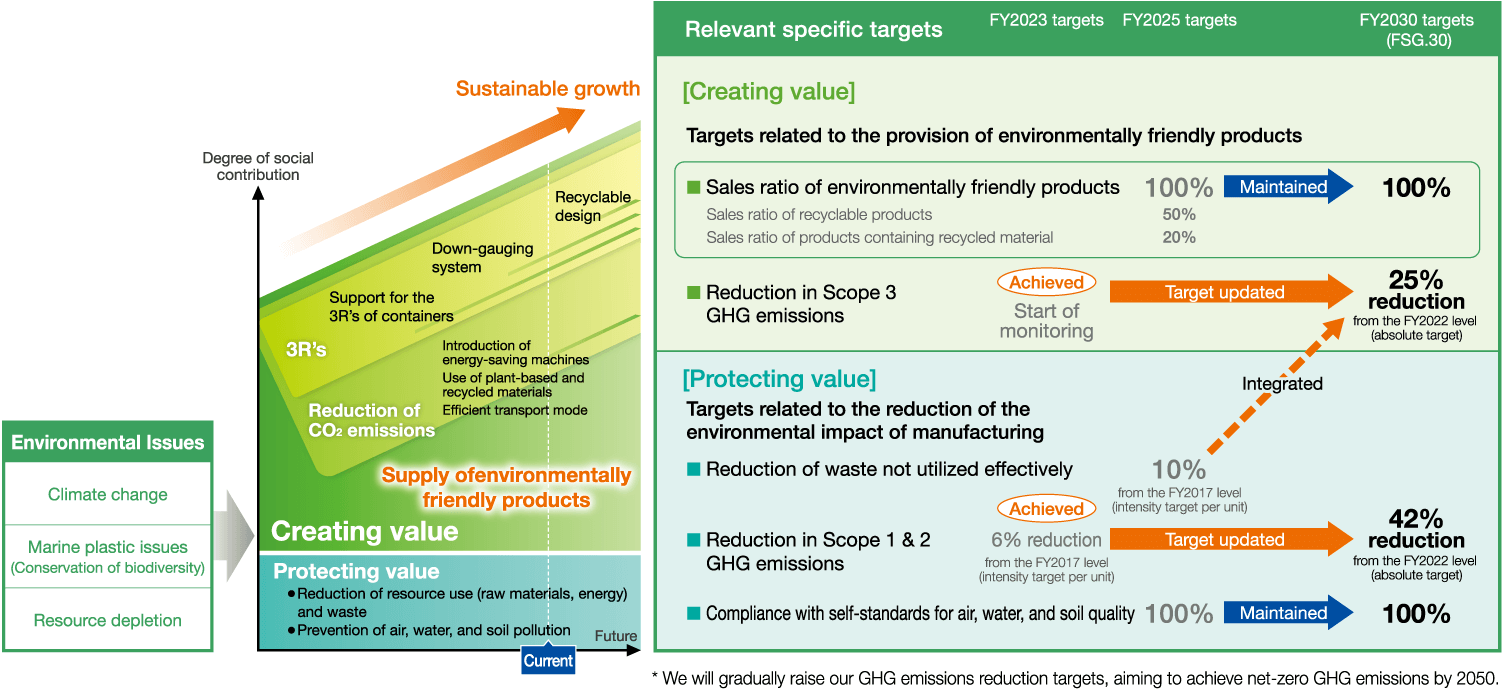

Fuji Seal Group considers climate change, ocean plastic issues, and resource depletion to be important environmental issues. In order to solve these environmental issues, we have formulated an environmental vision that focuses on "Creating Value" actions, such as the development and supply of environmentally friendly products, while building on "Protecting Value" actions that focus on reducing environmental impact in manufacturing. From FY2021 onward, in addition to targets related to sales of environmentally friendly products, we have also established targets for reducing the environmental impact of manufacturing. With regard to addressing climate change, we aim to achieve net-zero emissions by FY2050, and starting from FY2024, we have set a new target for reducing greenhouse gas emissions with a target year of FY2030.

For progress on each goal, please refer to the Integrated Report and ESG Data Book.

Environmentally Friendly Products

Creation of value: Provision of environmentally friendly products

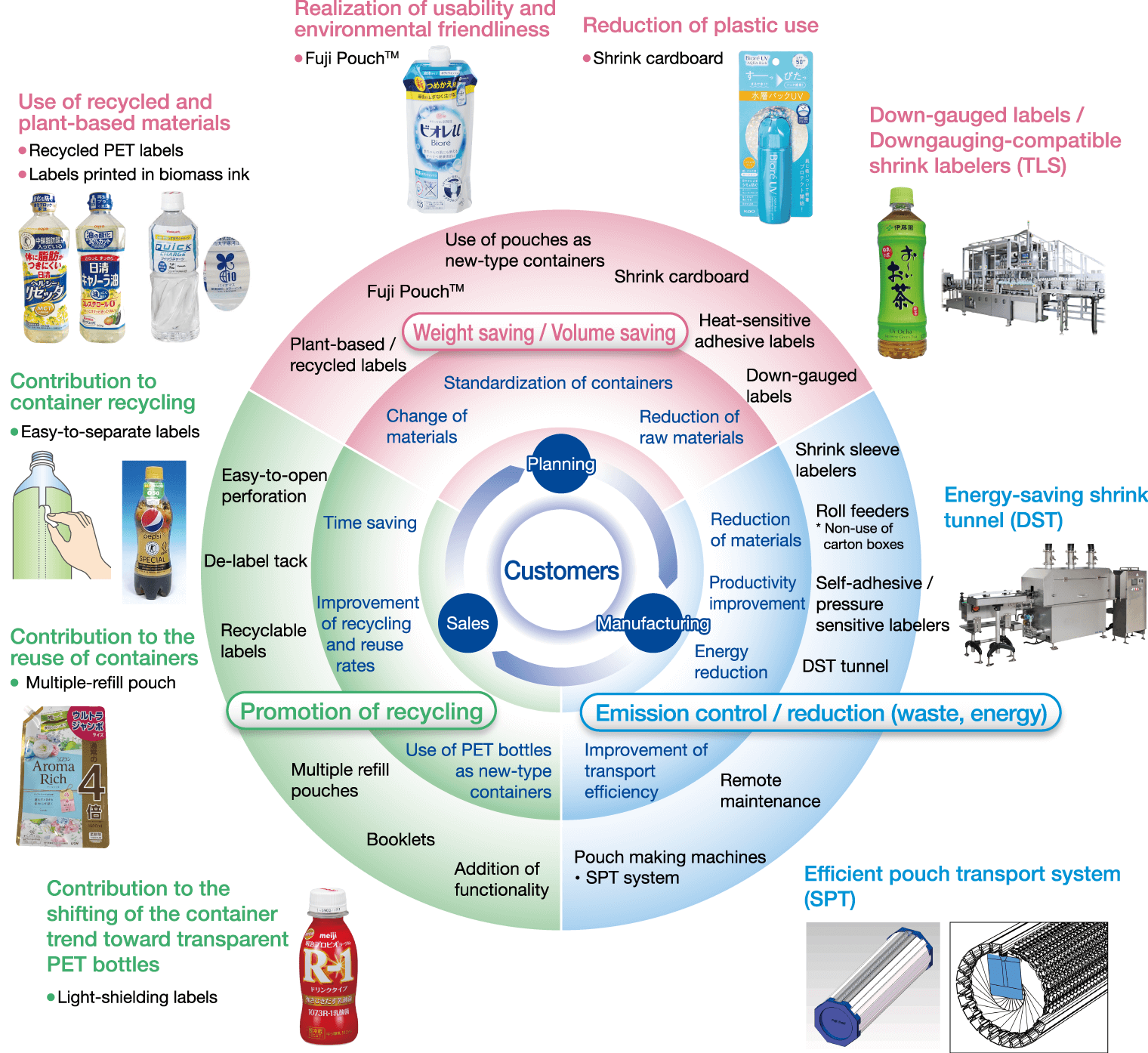

We have provided solutions for customers' issues for many years, with a focus on all business processes, including creation (development), production (manufacturing), and sales (marketing). We realize that we are now further required to identify potential problems and work with our customers and suppliers to resolve them by gaining a better understanding of each customer's business cycle, from planning to manufactur-ing and sales, as well as of their current products. This also applies to the resolution of environment-related issues. The following chart shows the path that we have traced while identifying and addressing various environmental issues, such as weight and volume saving, emission control and reduction, and promotion of recycling, in individual business processes.

We will continue to contribute to society by continuously providing environmentally friendly solutions.

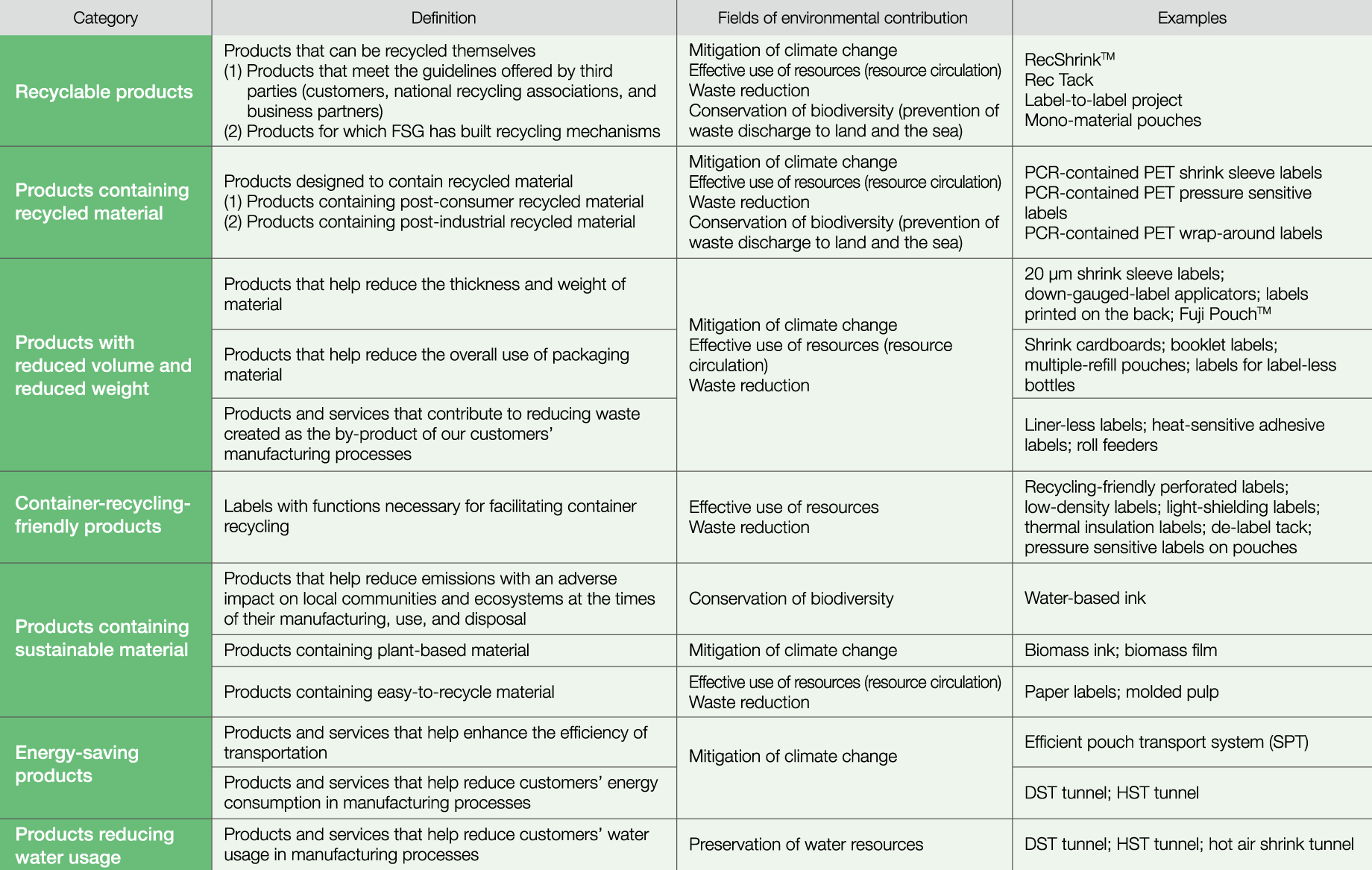

Definitions of categories of environmentally friendly products

The categories of environmentally friendly products are defined by the executive officer in charge of each region or each business to ensure that FSG’s business activities accurately reflect demand in each regional market and our customers’ views on the environment. The appropriateness of these definitions is reviewed by the Group Sustainability Committee as needed.

Initiatives for Reducing Environmental Impact

Fuji Seal Group is committed to manufacturing products that reduce the burden on the ecosystem and local environment. Through the production of shrink labels, pressure sensitive labels, pouch containers, packaging-related machinery, and other products, we aim to develop and produce environmentally friendly products, while at the same time reducing the amount of solid and liquid waste, wastewater, and exhaust gas (chemical substances and CO2) discharged, in order to reduce our impact on the environment. In addition, we collect ideas from a wide range of employees through TQM* activities, idea banks, and various projects, and hold regular meetings on energy conservation and environmental protection, as part of a concerted Group effort.

*TQM:Total Quality Management

ESG Education

Fuji Seal Group provides environment-related education in training for new employees, training for each departmental unit such as manufacturing, development, and procurement, and training related to ISO 14001 at ISO-covered business sites.Since 2022, we have been using the Integrated Report to provide education not only on the environment but also on ESG in order to deepen our understanding of environmental initiatives, governance systems, and risk management.

Fuji Seal Group has organized its contribution to the realization of a sustainable society into nine materialities (important tasks), which also correspond to SDGs. A new "ESG Declaration Card" has been created and distributed to employees in all regions in their native languages. All employees select a particular focus from the nine materialities, and describe their specific actions to realize it. We believe that it is very important for each and every employee to have a clear understanding of why we are working on ESG issues and what they need to do to address them.