Initiatives Related to Water Resource

Aiming to conserve water resources, Fuji Seal Group is developing technologies and supplying products that not only properly manage water during manufacturing, but also reduce water usage in the entire supply chain. Starting in fiscal 2021, we have set voluntary standards that are stricter than the regulations, and we are striving to control the quality of wastewater during manufacturing. We have also set targets related to sales of environmentally friendly products, including the provision of packaging machinery that enables customers to reduce water use in their processes.

Company-wide Targets for Water

Reduction of Water Consumption

Fuji Seal Group strives to provide products that have a small environmental impact and can be used with confidence by consumers by promoting appropriate resource management and recycling of water. Our plants in Japan use recycled water in part of the production process. The washing water used in our plants is filtered and recycled at least 10 tons/day.

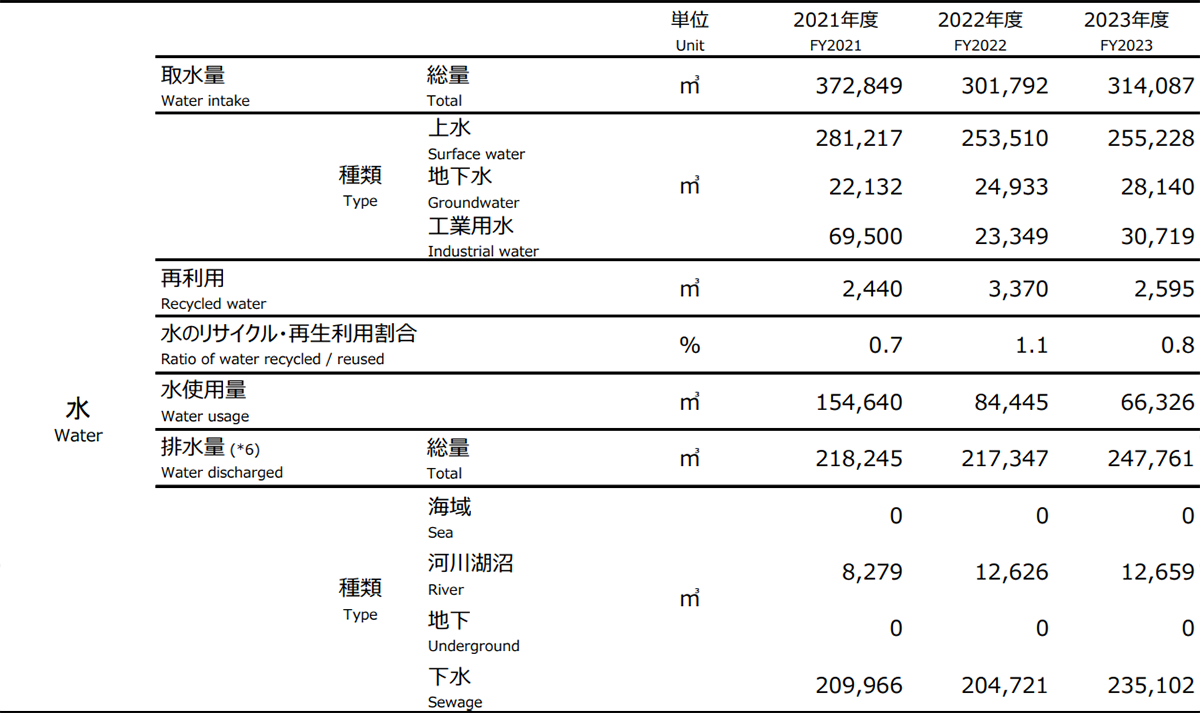

Investigation Results on Water Usage

Investigation of water risk at manufacturing sites

In the Fuji Seal Group's water risk assessment, we use the "WRI Aqueduct" provided by the World Resources Institute (WRI) to identify regions with high water risk, such as drought, at each of our bases. We define regions that are indicated as "Extremely high risk" for "Overall water risk" on the "WRI Aqueduct" as regions with high water risk, such as drought, overall, and in the 2023 survey, the Mexican Plant is a production base with a high water risk, but the percentage of water intake used by this plant is small when viewed from the perspective of the entire group, and the water intake at the Mexican plant in FY2023 was almost the same as in FY2022. As there is little change in the amount of water used in line with changes in production volume, and no significant increase or decrease is expected, we do not believe there will be any impact from this. In order to continue to understand the water risks at our manufacturing bases, we will conduct surveys using the WRI Aqueduct on a regular basis. In addition, if there is a risk of abnormal water quality at a factory or other facility causing operational problems, the executive officers in charge of each region (Japan, the Americas, Europe, and ASEAN) will report on this to the Board of Directors and in monthly reports.

Under the direction of the CEO, the executive officers and organizations work on water-related issues, and the Group Sustainability Committee, chaired by the COO, sets environmental targets, promotes action plans, checks progress, evaluates achievement levels, identifies and responds to management risks related to water.

Water related Opportunities

Application machines of shrink labels use steam to heat the labels to shrink. Therefore, we see the potential to increase machine sales by developing machines that use less water (steam) as a water-related opportunity in FSG.

Specifically, we have developed a high-efficiency steam tunnel with the goal of reducing water usage. By replacing normal steam with superheated steam, we are able to achieve thermal shrinkage using less steam than before. Water consumption has been reduced by 60% compared to our existing machines, bringing the cumulative CO2 reduction by reducing water (steam) usage was 8,246 tons over the six-years period from 2017 to 2022. This high-efficiency steam tunnel was launched in 2009 and has been adopted by many of our customers.