Initiatives Related to Chemical Substances

Fuji Seal Group is committed to the proper management and reduction of use of chemical substances with high environmental impact for the safety and health of local communities, customers, employees, and end consumers. In addition, in fiscal 2021, we established new voluntary standards for air, water, and soil that are stricter than the regulations, and are working to preserve the environment and maintain ecosystems by preventing local pollution, air, water, and soil contamination.

Company-wide Targets for Reduction of Chemical Substance Emissions

Efforts to Reduce Emissions of Chemical Substances

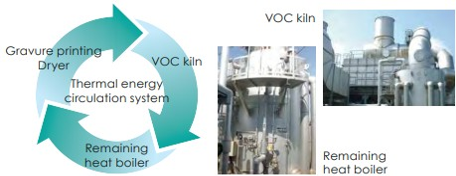

Fuji Seal Group is promoting manufacturing by developing production technologies and processes more environmentally friendly. For example, at the Tsukuba Plant, a thermal energy circulation system using VOC furnaces and waste heat boilers has prevented the emission of VOCs into the atmosphere and reduced fuel consumption. In addition, we are planning to gradually introduce appropriate treatment systems at plants that are not equipped with VOC treatment equipment.

Reduction and Proper Management of Environmental Impact Related to Chemical Substances

Fuji Seal Group (FSG) has established and is operating the Chemical Substance Management Regulations with the aim of preventing environmental pollution through appropriate management of chemical substances and reduction of environmental impact.

- Management and Operating Structure

- Under the supervision of the Board of Directors and CEO, a chemical substance management organization has been established and the roles of each site and department have been clarified to promote proper management of chemical substances and control of their use.

- Maintenance of SDS

- Safety Data Sheet (SDS) for chemical substances with hazardous properties used at FSG is maintained, and reconfirmed once a year at each workplace to update information and provide safety information.

- Risk Management

-

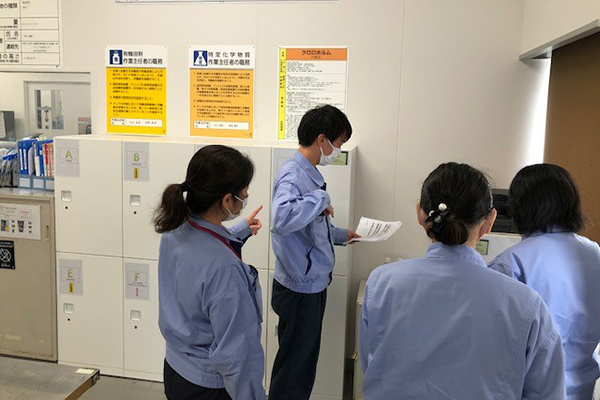

In departments where chemical substances are used, based on the SDSs, detailed regulations have been defined on first aid measures, fire measures, leakage measures, handling and storage precautions, and disposal precautions. They are displayed in easily identifiable locations and response trainings have been conducted based on them.

Training at the plant

Training at S×S center - Substance Balance Control

-

Detailed regulations are established at sites and divisions, and the amounts purchased, used, and disposed of are recorded in a control chart based on the "Hazardous Chemical Substances Control Chart", and checked by another employee. This is applied for the following chemical substances:

- (a)Hazardous substances specified in the Air Pollution Control Law and the Offensive Odor Control Law

- (b)Substances subject to environmental standards for the protection of human health as stipulated in the Water Pollution Control Law

- (c)Substances designated as hazardous industrial waste under the Industrial Waste Disposal and Public Cleansing Law

- (d)Designated chemical substances specified in the PRTR system of the Act on Confirmation, etc. of Release of Chemical Substances and Promotion of Their Management (Chemical Substances Control Law)

- (e)Substances specified in the Poisonous and Deleterious Substances Control Law

- (f)Hazardous materials specified in the Fire Service Law

Example of key management by electric key - Education

-

We provide education and training on the hazards and safety management methods for those who handle hazardous chemical substances in order to improve employee awareness and knowledge of chemical substance regulations.

Specifically, in Japan, each department conducts an annual in-house test on basic knowledge of chemical substances and precautions for their use, and license management is in place to ensure that only those who have passed the test are allowed to use the substances. - Promoting communication within and outside the company

-

In order to collect external information on the hazards and harmfulness of chemical substances, to ensure compliance with laws and regulations, and to promote the reduction of environmental impact, each site and department makes proposals to reduce the environmental impact of chemical substances, and strives to create clean factories (factories with reduced environmental impact).

In particular, for sites and divisions that use Specified Class I designated chemical substances (500 kg/year or more) and Class I designated chemical substances (1,000 kg/year or more) under the PRTR system in Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof, the amount transferred and emissions are calculated and reported annually to the prefectural department with jurisdiction over each site and division.

Global OHS (Occupational Health and Safety) Audits

The Fuji Seal Group recognizes the importance of thorough legal compliance and occupational health and safety, and has completed OHS audits conducted by an external organization in all domestic and overseas regions since 2020, and has promptly addressed recommended improvements. In addition, the Group is working to ensure compliance with laws and regulations and occupational health and safety through a management system in which self-checks are conducted based on checklists created during these audits to maintain compliance, and checklists are updated whenever laws or regulations are revised.