aPT Buisiness

Creation and challenge for future containers

FSG.30 is a very aggressive initiative, and it will be difficult to achieve it with a mindset that is an extension of the existing approach. In that sense, I believe that how we demonstrate creativity and take on challenges, or how each individual thinks and acts, is important for achieving it. I think it is a really exciting goal. Since our division is expected to make significant contributions through a new business, we need to build a new business pillar in addition to the four existing businesses.

Fuji Seal has made great strides in the area of packaging materials that make effective use of plastic film. However, with the rise in environmental awareness in recent years, label-less bottles and other eco-friendly containers have appeared as PET bottles for beverages. Although we see this as a major crisis, I believe there is definitely an opportunity there. We will realize the concept of bottle-less label containers as future containers for the aPT business to contribute to the realization of FSG.30.

The future containers we aim for

The environment surrounding packaging containers is becoming more severe every year, with issues such as global warming caused by CO2 emissions and marine pollution by plastic waste. In this situation, Europe, the Americas, and other countries are trying to regulate packaging containers. There are also moves to advance global regulations. We attach great importance to these trends. In such situations, it is important not to do what we can, but to do what we must, even if it means stretching ourselves. The issue with plastics is that most of them are made of petroleum-based resin. Ideally, if all plastic containers could be collected and recycled in a closed loop, we would not need to use any new petroleum-based resin.

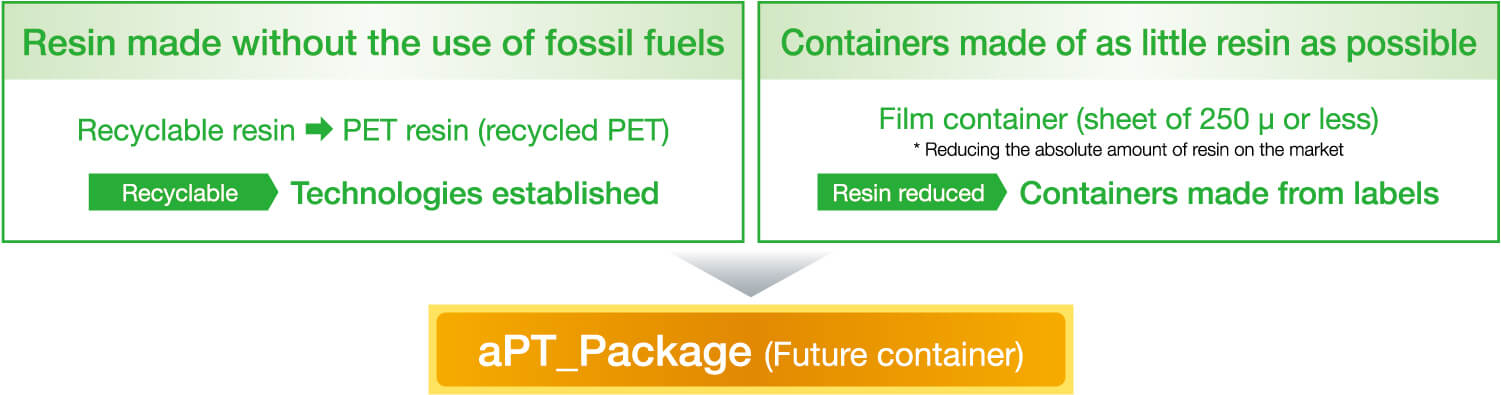

In the aPT business, we are developing future containers, defining them as 1) containers that are made of resin without the use of fossil fuels and 2) containers made of as little resin as possible.

Resin made without the use of fossil fuels in 1) can be considered a PET material for which mechanical and chemical recycling technologies have been established, in the sense that it can be recycled in a closed loop. The reference to containers made of as little resin as possible in 2) does not mean rigid containers, but rather film containers made of film. In other words, future containers are containers made of PET film.

Core technology for freely controlling PET resin

Advanced core technology is essential to making containers from PET film. Since the properties of PET resin change significantly depending on the temperature range, container manufacturing requires a thorough understanding and control of the resin properties in each temperature range.

Three core technologies are required to shape PET film into a container. The first is the technology to constitute the film layer. The film must be designed to meet physical properties such as low-temperature drop resistance and pressure resistance, and to improve usability. The second is the welding technology to form the film into a three-dimensional container, which is an important core technology for forming the container shape. The third is the technology to weld the film and a molded product. A container needs a spout or other outlet, and the film alone is not enough to complete it; the technology to weld it to a nozzle or other outlet is required.

In the aPT business, we have completed the development of these three core technologies and plan to release containers made using these technologies to the world in the future. PET film containers are manufactured using recycled resin and have a closed recycling scheme in which they are collected after use and turned back into containers. This makes them true future containers that satisfy both environmental and consumer value.